Adhesive Peel Tester agency|peel testing system : distributor c. Test duration - ABAA’s requirement is test until failure – other test methods are 100 or 30 seconds d. Termination of test - ABAA’s requirement is to continue the test until there is a rupture in the layers. Other test methods are to a specific load e. Number of pulls - ABAA’s requirement is for three pulls in a 39 inch by 39 inch . WEB27 de nov. de 2023 · Caio Cerqueira, Luan Alencar e Carlinhos Maia - (Reprodução/Instagram) Carlinhos Maia está promovendo mais uma edição da Casa da .

{plog:ftitle_list}

web16 de jun. de 2019 · Assistir Euphoria Todos os Episódios, Euphoria Online Dublado , Euphoria online Legendado no melhor site para assistir Séries Online .

ASTM D3330 Test Methods. ASTM D3330 includes six distinct test methods (A-F) to evaluate different types of peel adhesion. Here’s an overview: Method A – Measures 180° peel .

ASTM D1876 is a test method that measures the peel separation strength of two flexible materials that have been bonded together. This is commonly referred to as the “T-Peel” test because the sample looks like the letter “T” when loaded .c. Test duration - ABAA’s requirement is test until failure – other test methods are 100 or 30 seconds d. Termination of test - ABAA’s requirement is to continue the test until there is a rupture in the layers. Other test methods are to a specific load e. Number of pulls - ABAA’s requirement is for three pulls in a 39 inch by 39 inch .

ChemInstruments offers a wide range of adhesive and release testers including the AR-1000, Peel Adhesive Testing Machines, Release Machines and Unwind Machines for use in adhesive testing laboratories.

180° Peel Test: The most common test, peeling the substrate away from the adhesive at a 180-degree angle. Ideal for evaluating general bond strength. Ideal for evaluating general bond strength. 90° Peel Test: Similar to 180°, but with a 90-degree peel angle.There are many test methods used to determine the strength of an adhesive including peel, shear, cleavage, and tension tests. Peel tests are common for tapes, labels, coatings, and other bonded materials. There are three main types of peel tests including 90 degree peel test, 180 degree peel test, and a T-Peel test. The LoopTesting Equipment for Peel Adhesion. A multi-functional peel tester is used to evaluate the peel force in different peel angles, rates, and temperatures (Figure 1). The peel tester is capable of evaluating independent parameters of peel rate from 15-300 cm/min, angle from 0° to 180°, and temperature (by a

Adhesive Testing Equipment . A wide array of adhesives is used as a bonding agent for composites. Therefore, they need to be tested adhesion before a product can be used. . ISO 8510 -- Adhesives -- Peel test for aflexible-bonded-to-rigid test specimen assembly ;Benefits of Peel/Seal/Bond and Adhesion Strength Tester. The Presto Adhesion Strength Tester serves the purpose of measuring the enduring adhesion or peelability of self-adhesive pressure-sensitive materials. Peel adhesion, in this context, refers to the force needed to remove a pressure-sensitive coated material from a standard test plate under specified conditions, at .The bonded test pieces can also be exposed to potentially detrimental storage conditions such as extremes of heat, cold, artificial sunlight or immersion in product chemicals before testing for peel adhesion. Alternatively, the peel test can be made at high or low temperatures to simulate harsh product environments.

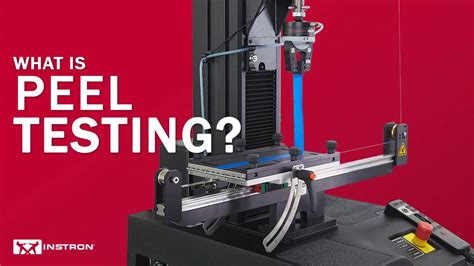

A peel test is a fundamental mechanical test that measures the properties of an adhesive bond. Peel tests involve applying a tensile force to a flexible substrate that is bound by an adhesive to either another flexible substrate (such as tape, thin film, or rubber) or a rigid substrate (such as metal, rigid plastic, or composite).Peel testing of adhesive and pressure sensitive tapes is used for quality assurance, and provides a means of assessing uniformity of the adhesion of a given type of tape. The assessment may be within a roll of tape, between rolls, or between production lots. Adhesive properties for tapes are measured using a standard test surface, a specified angle and test .ASTM D903 | Adhesives | Peel Testing. ASTM D903 is a common test performed for determining the strength of adhesive bonds. In the following procedures, a piece of tape or adhesive is bonded to a standard material and peeled backwards at a 180 degree angle. The main calculation determined through this ASTM standard is average peel or stripping .The ADMET eXpert 7601 adhesive and peel testing system has been designed to allow users to perform a wide variety of adhesive tests on a single easy to use and compact instrument. You can confidently report results knowing that the system has been engineered to meet all accuracy requirements specified in major standards organizations including .

Work with us to find the right equipment for your ASTM standard ASTM D3330 | Adhesives | Peel Testing Pressure sensitive tape is used in a variety of applications including duct tape, electrical tape, masking tape, packaging, double-sided tape, bandages, medical devices, and other uses. ASTM D3330 includes six different methods for testing theTest Procedure: Clamp each ends of the t-peel specimen in separate test grips of the universal tester / tension testing machine. Separate the specimen at a rate of 127 mm (5.0 in) /min for (5-in.) length of the bond line. Specimen size: Specimens are cut from a T-peel panel to 25.4 mm (1.0 in) long x 300 mm (12 in) wide. Ten specimens are .

what is peel testing

PSTC-101 is a standard test method to measure peel adhesion strength in pressure s. FTM-9 Pressure Sensitive Tape Loop Tack Test Equipment. Loop tack tests provide the means of assessing the most important and yet the hard. ASTM D903 180 degree Peel Strip Strength of Adhesive Bonds. ASTM D903 is a standard test procedure to determine the . (a,b) The intra-test CV trends changed to a decreasing trend after peel rate of 0.707 mm/sec for both PTFE and PEEK demonstrating that the asynchronous failures of filaments of adhesive layer is .first strip of tape and tested for peel adhesion as described in Test Method A. 4.3 Test Method C—Double-Coated Tapes: 4.3.1 Face Side Adhesion—The double-coated tape is ad-hered to a stainless steel panel (or other surface of interest), liner side up. The liner is removed and the exposed adhesivewhich time the force required to effect peel is measured. 4.2 Test Method B—Adhesion to Backing, Single-Coated Tapes—A strip of the tape under test is applied to a rigid panel. A strip of the tape under test is applied to the backing of the first strip of tape and tested for peel adhesion as described in Test Method A.

Gas Permeability Tester discounter

Test angle is permanently set for 180° testing; 10 pound load cell is included with the machine; Capable of pulling up to 10 lbs (4.5 kg) Test samples as short as 1/2” to as long as 6” (12-150 mm) Designed to accept standard 2” x 6” peel panels (50 mm x 150 mm) Increments of 1.25 - 11.25 cm / .5-4.5 in.Standard test technique for peel adhesion of pressure-sensitive tape; ASTM-D3330-B-E ; Standard test procedure for peel adhesion of pressure-sensitive tape (ASTM-D3330). Standard test procedures for rubber properties; adhesion to flexible substrates (ASTM-D413) and rigid substrates (ASTM-D429)

The data we provide assists material engineers in the selection of materials in global markets. It includes adhesive strength testing such as tensile, shear, and peel data, as well as other adhesive property tests (e.g., impact, odor, and aging). Testing can be performed in hot/wet/dry conditions at ambient, elevated, or reduced temperatures.

Gas Permeability Tester advice

peel testing system

A number of standard test methods are used in the U.S. to measure the peel adhesion or bond strength of pressure-sensitive labels. These include ASTM D 903, ASTM D 3330, ASTM D 6252 and the TLMI 180° Peel Adhesion-Face Stock test method. In addition, as the need to compare test results from other parts of the world increases, it is important to be .Adhesive peel tester Product Introduction: Adhesive peel tester is an multifunctional tester, a ccurate and effective peel tester testing with 90 ° and 180 ° tape peeling, peel tester be with s ervo motor drive, precision ball screw drive, the computer set the test speed directly for adhesive force the physical property of strength resistance.An adhesion tester measures the force required to detach a coating from a substrate. Often called a pull-off adhesion tester or peel tester, an adhesion tester applies a large amount of force to evaluate a coating's bond strength. When measuring peel force or adhesiveness, the nature of the substrate's surface plays a significant role. However .

Peel Adhesion Tester: An Overview of the Machine. A peel adhesion tester is a specialized instrument designed to measure the adhesive strength of materials, including tapes, labels, films, and other packaging components. It simulates real-world scenarios by applying a controlled force to peel apart two surfaces bonded with adhesive. Here's how .

Adhesion is dependent on the “wetting-in period”. It is important that peel tests are conducted within a specified time period (as provided by the manufacturer. Material and substrate temperatures will affect the peel adhesion recorded. Temperature conditions should be recorded to allow a meaningful comparison of test results. Peeling takes a wide array of forms. In the most basic sense, a peel test can consist of (1) a laminate comprising of two (or more) layers peeled apart, often at the interface or (2) an adhesively bonded joint in which two substrates are joined by an adhesive layer and then peeled apart, or (3) peeling of a single, adhesive material from a substrate or itself.

peel testing machine

Resultado da OXIN é um produto natural que combina fitoativos para prevenir doenças e rejuvenescer a pele e outros tecidos. Saiba mais sobre as indicações, .

Adhesive Peel Tester agency|peel testing system